Robotics

I spent a bit over ten years in and around Sydney University's robotics labs. I did a combined B.E./B.Sc., with my engineering major in Mechatronics, and my honours thesis implementing path planning and obstacle avoidance for a pair of autonomous ground vehicles (AGVs).

I then joined the Australian Centre for Field Robotics as a Ph.D. candidate, spending three and a half years on a variety of projects. This culminated in a thesis that solved the Time-Optimal Active Decision Making problem - how best to optimise a dynamic system when the computational time to perform the optimisation must also be minimised.

In 2022/23 I hand-built the first prototype of Control Bionics' DROVE system - an add-on kit used to add autonomous indoor navigation to powered wheelchairs for patients with MND, CP, and other conditions that compromise their mobility. I calculated all the co-ordinate transforms by hand and wrote all the software myself without the use of ROS due to medical-software constraints on the use of software of unknown provenance. In all honesty I'm amazed it works as well as it does...

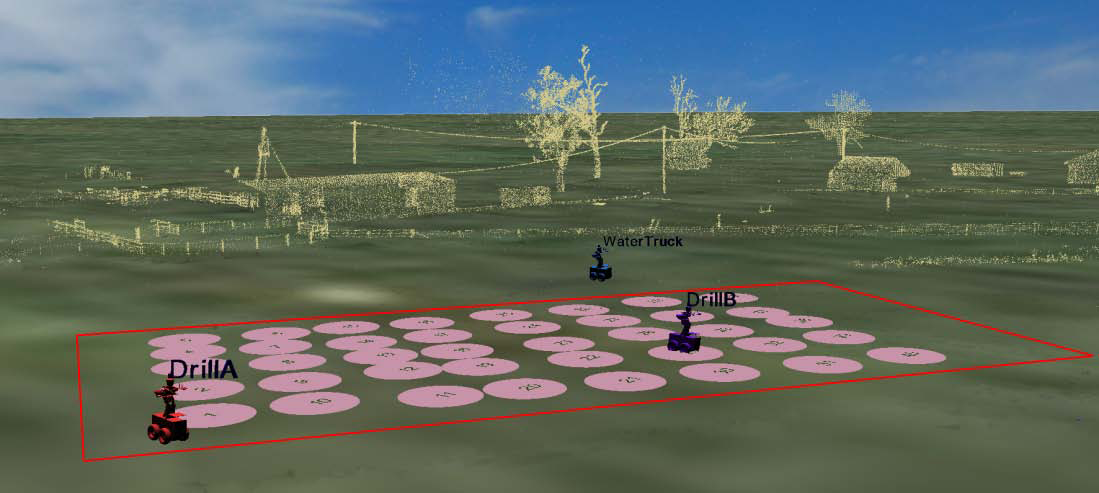

In 2023/24 I took on a consulting project with a large US robotics and automation provider, who had been selected as the prime supplier to a multi-billion dollar project in Western Australia. That turned into an ongoing relationship where I provide robotics and engineering management advisory services.

I then joined the Australian Centre for Field Robotics as a Ph.D. candidate, spending three and a half years on a variety of projects. This culminated in a thesis that solved the Time-Optimal Active Decision Making problem - how best to optimise a dynamic system when the computational time to perform the optimisation must also be minimised.

In 2022/23 I hand-built the first prototype of Control Bionics' DROVE system - an add-on kit used to add autonomous indoor navigation to powered wheelchairs for patients with MND, CP, and other conditions that compromise their mobility. I calculated all the co-ordinate transforms by hand and wrote all the software myself without the use of ROS due to medical-software constraints on the use of software of unknown provenance. In all honesty I'm amazed it works as well as it does...

In 2023/24 I took on a consulting project with a large US robotics and automation provider, who had been selected as the prime supplier to a multi-billion dollar project in Western Australia. That turned into an ongoing relationship where I provide robotics and engineering management advisory services.

My Ph.D. research answered the question of how you solve problems when the problem itself is changing while you try to solve it. Imagine you're trying to work out the fastest route from one side of your city to the other, but while you're working it out people keep having car accidents that block roads, tow trucks keep clearing previously blocked roads, and the local council is constantly building new roads (really really quickly!) Adding to that, even when you've worked out what you think is a good route, while you're driving it the roads are still changing constantly.

My work showed that in most interesting applications of this problem - not just roads and driving, it applies in lots of other contexts as well - the time you spent working out a solution is quite large. If you want the 'perfect' solution, it could be so large that you would have been better off to drive a slower route but not spend so much time thinking about it in the first place.

I found a way to quantify all these factors, and a way to solve what you really want; not "find me the fastest route across the city", but rather "get me to the other side of my city as fast as possible". I was also able to prove that my method was guaranteed to be at least as fast as any other method, and most of the time was much faster.

My work showed that in most interesting applications of this problem - not just roads and driving, it applies in lots of other contexts as well - the time you spent working out a solution is quite large. If you want the 'perfect' solution, it could be so large that you would have been better off to drive a slower route but not spend so much time thinking about it in the first place.

I found a way to quantify all these factors, and a way to solve what you really want; not "find me the fastest route across the city", but rather "get me to the other side of my city as fast as possible". I was also able to prove that my method was guaranteed to be at least as fast as any other method, and most of the time was much faster.

I was later employed in the Rio Tinto Centre for Mine Automation as a research fellow and systems engineer. I designed and implemented the communications protocols, language, and software infrastructure to allow different vehicles to co-operate across the entire mine environment. This work was critical to Rio Tinto's "Mine of the Future" programme, and was scaled-up for production use by Rio Tinto's internal team. It will save them several haul trucks worth of cash per year through efficiency gains and avoiding vendor lock-in.

In the research side of this role, I developed a collection of non-holonomic planning algorithms that efficiently pre-process the complex manoeuvres for different vehicle types, allowing for real-time deployment in the field. Better motion control leads to lower maintenance and fuel costs, improves production quality, and can lead to enhanced mine efficiency.

In the research side of this role, I developed a collection of non-holonomic planning algorithms that efficiently pre-process the complex manoeuvres for different vehicle types, allowing for real-time deployment in the field. Better motion control leads to lower maintenance and fuel costs, improves production quality, and can lead to enhanced mine efficiency.